The recent increase in stock-outs has impacted consumers’ purchasing decisions. How prepared is your business to manage these stock-outs?

It only takes two strikes, and you are out! Experiencing stock-outs will impact your sales and how customers engage with your products in the future. In a recent survey conducted in November 2021 by Netstock, a leading inventory software provider, 43% of consumers indicated they are more likely to ditch a product after experiencing two or more stock-outs.

As consumers experience ongoing stock-outs the more exposed they are to substitute or alternative products. 65% of respondents indicated they tried a new brand because an item was out of stock, sending a clear message that this is an ideal opportunity for competitors to win over these consumers.

Over the last 18 months, it is no secret that the COVID-19 pandemic has added additional strain on the already fragile global supply chains. Consumers believe the incidence of out-of-stock products is not likely to improve, with 71% of respondents who have experienced stock-outs in the last 30 days stating popular items will likely still be out of stock in the next three months [December 2021-Feb 2022].

To safeguard your business against the effects of stock-outs, you need the right tools to measure and plan your inventory to meet your demand. The erratic and unpredictable nature of what the consumers want and where they purchase the product adds enormous pressure when managing and forecasting inventory. Businesses with visibility across their supply chain are better prepared, offering their customers transparency and differentiating themselves from their competitors.

Netstock surveyed 400 USA consumers who had experienced out-of-stock items in the past 30 days.

These key takeaways showcase how consumers react towards products or brands being out of stock:

#1 Takeaway: 82% of respondents who shopped exclusively or mostly online experienced stock-outs as opposed to the 67% who primarily shopped in-person. Retailers need to increase communications and get creative with their customers! Incorporate an effective communication plan into the supply chain planning process, ensuring customers are fully aware of any out-of-stock products or if products are low on stock. Get creative with incentives or offer replacement products to satisfy customers.

#2 Takeaway: Respondents who have either Walmart or Amazon Prime subscriptions are not immune to experiencing stock-outs, with 71% of respondents stating they expect to experience more stock-outs over the next three months.

#3 Takeaway: 90% of respondents who preferred to shop mainly or exclusively online for baby products experienced the most stock-outs from the 11 item categories surveyed.

#4 Takeaway: 22% of respondents who shopped mainly or exclusively online for electronic equipment experienced the least amount of stock-outs from the 11 item categories surveyed.

#5 Takeaway: by item category summary, healthcare items showed some of the highest stock-out occurrences where 65% of respondents tried another brand. The healthcare category also had the highest percentage of respondents (40%) that identified as shoppers that “always read online reviews before purchasing a product”.

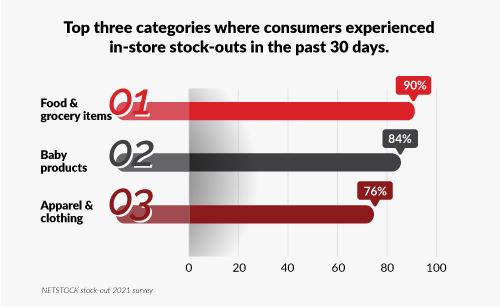

The top three categories where consumers experienced the most in-store stock-outs:

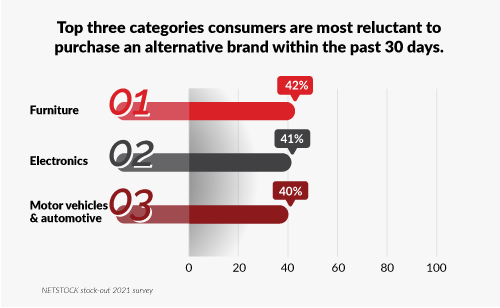

Products or brands are viewed differently by consumers. There are those items that consumers are not prepared to substitute for an alternative either online or in-person once having experienced a stock-out.

How consumers view comparable products:

When asked what consumers would do if an item were out-of-stock the next time they were shopping:

- 43% of consumers indicated they would look for a similar product if the preferred brand were out-of-stock.

- When asked about experiencing a second in-store stock-out of the preferred brand, 42% of respondents indicated they would buy a comparable product.

- Having experienced a stock-out for a second time, 28% of respondents said they would consider an identical product online rather than in-store.

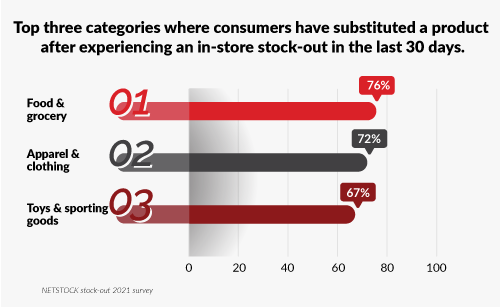

Overall, consumers are open to trying other brands, and in a world where most of us expect instant gratification, consumers also crave convenience. Consumers will likely purchase a product of similar quality that is readily available. Only a small percentage of consumers are willing to wait for their product of choice to become available.

It’s not surprising that consumers will quickly use substitute brands in the top three categories above as these are mostly necessity items. If consumers start to stockpile these items, businesses will experience a shift in consumer demand, leading to more unpredictable surges.

Does your business have inventory visibility to avoid stock-outs?

The shortages of raw materials and extended supplier lead times have drastically affected product availability resulting in businesses experiencing stock-outs. Improving how you manage your inventory will help decrease the occurrences of stock-outs.

You need complete visibility of:

- Your key inventory indicators: to gain actionable insights to ensure you can meet demand.

- How well your suppliers perform: knowing if they deliver on time and in full.

Inventory visibility:

- If you manage 1000’s of SKUs, knowing which items need attention can be a challenge. Classifying your items according to the item’s sales and velocity will immediately identify the high-value fast-moving items. These items are critical as they make up the bulk of your sales, and you don’t want to run out of stock of these items.

- Work off a dashboard will allow you to manage by exception and provide your inventory planning team insights into the items that need immediate attention. For example, the dashboard can show you which items need to be replenished so you can avoid stock-outs.

- Accurate inventory forecasting helps you plan for future demand. Your forecast is critical in determining the optimal recommended order quantity and should reflect the actual market demand. Understanding your key item’s risk profile will also influence the safety stock you need to ensure you avoid stock-outs.

The importance of supplier management:

- Develop good relationships with your suppliers. Understanding their challenges can help you proactively identify which items may be at risk of stocking out.

- Use a tool to review your suppliers performance, and whether they are delivering on time and in full.

- Diversify your suppliers. Knowing your key items, you can look to source alternative suppliers to ensure you can meet demand on time.

Your customer holds the key to your business. Placing your customer at the center of your supply chain planning will allow you to prioritize your time and resources on the right stock.

Irrespective of whether your customers are purchasing products online or in-store, having visibility of your inventory can help you avoid stocking out on the essential items your customers want.

Stay ahead of your competitors!