The ABC analysis categorizes your inventory, identifying high-value, fast-moving items that help demand planners work efficiently to meet demand and increase sales.

Demand planners must ensure that the inventory investment is balanced: avoiding stock-outs by providing enough stock to meet demand and reducing excess stock in the warehouse due to over-ordering. It may sound simple enough; however, each stock item is different, holds its own value, and there are risks and hidden costs associated with each stock item.

It isn’t easy to view hundreds, or even thousands, of SKUs [stock keeping units] every day and make an informed decision on what to buy, what’s running short, and what items you have too much of.

So, how can demand planners manage stock efficiently with all these moving parts and reduce inventory costs without experiencing stock-outs?

A good starting point to managing inventory is determining the difference between each stock item and then classifying items using an ABC analysis.

What is the ABC analysis?

The ABC analysis is an inventory classification technique based on the Pareto Principle that supports the 80/20 rule that 20% of your items will give you 80% of your sales.

The purpose of using ABC analysis is to classify inventory according to various criteria to help demand planners free up time and resources by allowing them to focus on stock items that produce the most turnover. Once you classify your inventory, you can also identify the items that are highly dependent on each other. This information is critical when setting your inventory policy.

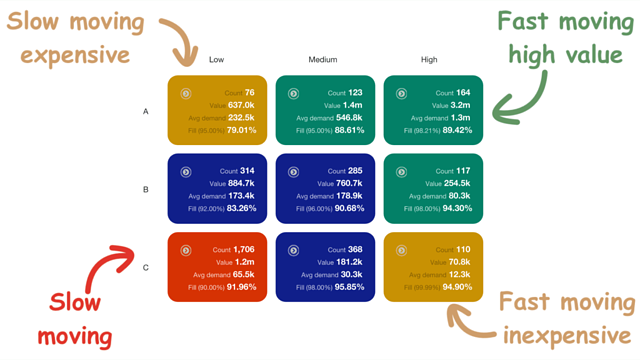

You classify each stock item into the following categories:

- A = highest value, i.e., your best selling items

- B = medium value, i.e., your mid-range selling items

- C = least value, i.e., your remaining items.

Managing inventory is a collaborative process and can not happen in isolation from the rest of the business. The same thinking applies when classifying your inventory. Demand Planners can’t only focus on ABC item value, they also need to consider the sales velocity of each item such as:

- H = High velocity

- M= Medium velocity

- L= Low velocity

An example: A high-value, low-velocity item like a car engine is planned and managed in your inventory system differently from that of a low-value, high-volume item like nuts and bolts, even if the annual turnover is the same.

Incorporating the sales velocity as part of your classification matrix will ensure your inventory classifications are more precise.

In essence, an AH item is a high-value, high-velocity item is critical as it’s a high-value fast moving item that makes up the bulk of your sales – you want to be extra careful not to run out of stock on these items.

In contrast, a CL item is a low-velocity, slow-moving item.

What do you have to take into account for each stock item?

Each stock item has its specific characteristics and these determine how the stock should be classified. They all have different:

- Origins

- Life cycles

- Levels of importance, where some items are dependent on others, such as raw materials, to produce an end product.

The type of business you operate will also determine how you classify your items, and often, more than one classification criteria is required to achieve an accurate result.

For many companies, the lack of inventory classification makes the challenge of managing inventory effectively almost impossible. Using the ABC classification matrix is the foundation of any successful inventory management solution and allows you to base your inventory policy and procedures around them.

Discover how Netstock automatically classifies your stock.

Five benefits of an ABC analysis in inventory management

1) Fight fewer fires and focus on stock items that impact your bottom line

Whether in life or while managing inventory, you need to pick your battles! When managing your inventory, you cannot fight every challenge that pops up every day. So, how do you choose which challenge you want to take on? By classifying your inventory, you can focus on the right challenges. Since the stock items are in groups, you can stop wasting your time on the unimportant items and focus on the items that make a difference to your business: the items that bring you the turnover – your AH items.

2) Invest working capital on products that deliver sales

Inventory management would be easy if we had infinite working capital. You could stock as much inventory as was needed to achieve a 100% fill rate on all items. In the real world, you need to take into account your working capital constraints. Efficiently deploying that working capital can make the difference between mediocre sales and excellent sales. By now, you’ve probably guessed that you can use your ABC & HML analysis to achieve this. Looking back at the Classification Matrix, it’s easy to see that there’s no point investing large amounts of capital into the CL items: they don’t contribute much to the bottom line. Centralize those CL items in a Distribution Center if you need to have them available rather than keeping them in multi-locations for “just in case.” Instead, invest most of your working capital into the AH items. Not only will they increase inventory sales and profit, but they will also move quickly, and turn your money over faster.

3) Manage essential items more closely

If you have an item flagged as a Potential Stock-out, your reaction will differ depending on its classification. CL items can be ignored, at least until a later time. AH, items, on the other hand, should be managed immediately. The opposite is also true. When an CL item gets flagged as having Surplus Purchase Orders for example, you will respond immediately by cancelling the order if you can because those extra items will sit in your warehouse for a long time and won’t make any profit when they are eventually sold.

Remember, if you order too much of a high-velocity item, it may not be a massive problem as those items move quickly. You should only worry about these items if you ordered a few months’ worth of extra units as an extra week or two of high-velocity items won’t hurt your inventory.

4) Let an inventory management solution manage less important items automatically

You can experience stock-outs if you get the forecast wrong, even by 20% on your AH items. There are probably thousands of CL items where a 20% forecast error is not even a blip on the radar screen. The solution here is to invest in an automated forecast engine to manage those low value, low velocity items for you so you can spend your time on the items that matter.

5) Increase your profit!

You are guaranteed to increase your profits if you invest your working capital, time, and energy into the items that give you the highest return on investment. For many businesses, the lack of inventory classification makes the challenge of managing inventory almost impossible. If your demand planning team is always busy but never seems to achieve much, this indicates a lack of focus that item classification can bring. Remember that if everything is important, then nothing is important!

Select the right tool to classify your inventory.

Many businesses are still using spreadsheets to manage their inventory classification. It doesn’t take much to see how complex a spreadsheet needs to be if you want to execute this accurately. Perhaps setting up an ABC analysis is simple with a few stock keeping units, but as soon as you introduce the second classification set, the HML, or a few hundred SKUs it becomes clear that a spreadsheet is not the ideal tool to use.

Besides the formulas and macros, the chance of human input error is extremely high, not to mention how time-intensive this becomes from a data re-entry and continual update viewpoint.

There is no denying that spreadsheets have their place as a business tool, but should they be used to manage inventory complexities?

Your demand planning solution and your ERP: Classifying inventory is the first step towards better inventory health. Using a demand planning tool like Netstock, demand planners can effectively:

- Set up the classifications for each SKU

- Set up inventory policies using sales history and supplier’s performance from the ERP

Once all the data has been captured and has run through the numerous algorithms, you receive a dashboard summary that allows you to manage your inventory proactively.