A customer case study

The Sales Manager had been under pressure to get rid of excess stock. He finally focused on the task and very successfully disposed of a large quantity of a particular item. To his satisfaction, that huge pile in the warehouse was now down to it’s “maximum level” and the pressure was off him.

In the next monthly ordering cycle he noticed the item had appeared on the reorder report and promptly stopped the order being placed. He was determined this item would not land up being in excess again.

He proudly explained all of this to me. When I asked if he had disposed of the excess stock quantity calculated by the Inventory Management System, he looked a little sheepish and said No!

We looked at the Inventory Management System. The item now had a Potential stock out status.

He was horrified to find the item would be out of stock for the next three months!

What on earth went wrong he asked?

He had disposed of the stock above the maximum level. Why had this not worked?

- When calculating the quantity to dispose of, that fact that the item had a 6 month lead time and that there were no open purchase orders on the item had not been considered. The boss had said, “get rid of the pile of stock in the warehouse”. He focused on doing just that; to his credit he had been very successful.

Let’s take a look at why it all went wrong.

- The bottom line here is that the quantity of excess that could be safely disposed of had not been determined prior to taking action. In other words, the “disposable excess” had not been calculated

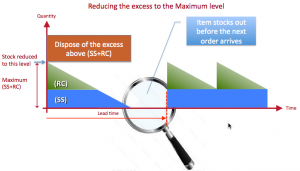

- The disposal action had reduced the stock to the maximum level. Once the cycle and safety stock has been consumed, the item will stock out until the next delivery is received a lead time later

- By the way, as far as non-stocked and obsolete items are concerned all free stock on hand is disposable excess. The lead time does not play a role at all

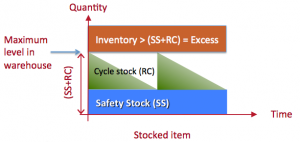

- Stocked items require a different perspective. Depending on the target fill rate and factors such as the replenishment cycle, lead time, forecast and supply risk, a level of safety stock in addition to the cycle stock is required. This is illustrated in the diagram below

- Although the stock above the maximum level (SS+RC) is excess, retaining excess stock to prevent a stock out over the lead time is required

- Because there were no purchase orders in the pipeline in this instance, excess stock equivalent to the expected sales over the six month lead time must be held in stock. By the time the next order arrives, the excess stock will have been consumed

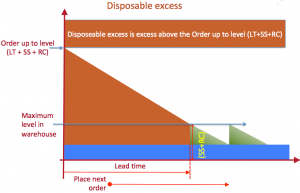

- The correct measure for determining the disposable excess is to only dispose of excess above the order up to level (SS+RC+LT). The following diagram illustrates this

However, there is one more aspect to consider.

In our case study, the disposal action to the customer base at a discounted price encouraged customers to over-stock and purchase quantities in excess of their normal requirements.

- Over-stocked customers will not order on us again until their excess has been consumed. The forecast in the system MUST therefore be lowered to reflect this

- The increased sales resulting from the disposal action will lead to higher computer generated forecasts and therefore higher orders. This is another reason why the forecasts must be reviewed and adjusted

If this is not done, the combination of increased computer generated forecasts and reduced demand will without doubt result in excess stock being created. Back to square one!

Further refinements to the “disposable excess” quantity that are often considered include reducing the quantity available for disposal by the estimated demand for a further few replenishment cycles in order to delay the requirement to place the next order. Disposing of excess creates a certain amount of instability in the supply chain and a conservative approach for items with long lead times is usually wise.

An honest appraisal of what caused the excess stock will be of great benefit, especially if the lessons learned are applied in the business. For example, in this case study, it is very likely that the open purchase orders were being identified as surplus to requirement and if they had been cancelled or delayed, the outcome would have been entirely different.

This case study highlights just one of the pitfalls of excess disposal. There are many other pitfalls. These will be addressed in later blog posts.

An Inventory Management System that identifies “Disposable Excess” and “Surplus orders” supported by business procedures that clearly define the actions to be taken by the people in the team responsible for managing these risk areas will considerably reduce the risk of this particular pitfall.

PS: With the benefit of hindsight, applying the correct measure to the item in our case study, revealed it did not actually have any disposable excess.