Stepping into supply chain planning for manufacturing is like tackling a maze of hurdles. With different links in the chain, it’s crucial to plan supply and demand just right to ensure manufacturing runs smoothly. From predicting demand to managing inventory, every part needs careful attention. However, amidst this complexity lies a golden opportunity: optimization. Optimizing manufacturing processes isn’t just a lofty goal; it’s the cornerstone of success in today’s competitive landscape. Efficiency, cost-effectiveness, and superior quality are the rewards of a well-optimized manufacturing setup. In this blog, we’ll delve deep into the intricacies of manufacturing optimization, exploring strategies and solutions to help you navigate this maze and emerge with a finely tuned, competitive advantage

In this article, we’ll discuss strategies for optimizing your manufacturing planning process and overcoming the common challenges businesses face.

Table of contents:

1 What is manufacturing planning?

Manufacturing planning in terms of inventory encompasses strategically forecasting, procuring, and managing raw materials, components, and finished goods to meet production demands while minimizing costs and optimizing efficiency. This includes processes such as demand forecasting, inventory classification, production scheduling, capacity planning, and bill of materials (BOM) management, ensuring the right inventory levels are maintained throughout the manufacturing process while considering production capacity constraints and the intricate relationships between various components and finished products.

2 The state of manufacturing planning

As a manufacturing business, you probably have an existing solution that enables you to set your inventory levels, plan your manufacturing, and suggest raw materials and components you need to order to support your manufacturing process. This may include Excel spreadsheets with formulas, reports complementing your ERP, or native ERP functionality.

However, despite these solutions, many businesses still need help with stock-outs, excess inventory, and spending excessive time creating and producing purchasing and manufacturing plans.

Henry Ford once said, “If you always do what you’ve always done, you’ll always get what you’ve always got.” Isn’t it time to look at your current processes and see if there is a better way to improve your inventory performance and make your supply and demand planning process more efficient?

29% of Netstock customers say their biggest inventory issue was stock-outs

When you run out of stock, you risk losing sales. If you continue to run out of stock on key products, you might lose the customer entirely, which will significantly impact your sales revenue.

26% of Netstock customers say excess stock was their biggest problem

Excess stock is rather insidious because it has a double whammy. Imagine a manufacturing facility with constrained capacity. If you are making something where there is already enough stock, you are essentially making excess stock and utilizing much-needed capacity for items that are potentially running out of stock.

45% of Netstock customers report significant time and effort spent preparing data for planning

Time spent compiling data and reviewing numerous reports means less time is spent ensuring the best possible order is produced.

3 Fundamental inventory processes

Whether you’re a distribution or manufacturing business, certain fundamentals will drive your inventory process.

Let’s explore these fundamentals:

If your vendors, these could be external vendors, a manufacturing facility, or a distribution center, always delivered on time and in full, and you could predict what your customers would take and when they would take it, planning inventory would be simple.

Planning in manufacturing starts by defining the planned requirement at the finished product level. Only once we have that can we start looking at the component-level planning and demand dependencies. In consequence, at a finished product level, all you need to do is match the supply and demand. The only things causing you to hold inventory would be minimum manufacturing runs, MOQs from external vendors, or trying to fill containers (if you are importing from overseas).

In reality:

- vendors deliver late and short supply, and

- we under forecast demand

In both of these situations, we run the risk of running out of stock.

The reverse is also true:

- vendors deliver early and over-deliver and

- we over forecast demand

In both of these situations, we run the risk of creating excess stock.

To optimize your inventory, you need to have a tool that automatically monitors these two risk factors and uses this data to dynamically adjust your safety or minimum stock levels to cater to these demand and supply variations.

In any business, we find constant pressure from finance to reduce inventory, while marketing and sales are continually trying to inflate the inventory to ensure that stock-outs leading to lost sales are minimized.

Without a coherent, realistic inventory policy that balances the cost of inventory against the cost of stock-outs and lost sales, most businesses will be like a rudderless ship, constantly oscillating between periods of significant excess and substantial stock-outs.

That’s why you need a platform that enables you to set inventory policy, balancing the cost of capital against the cost of lost sales while covering the inventory risk.

4 The importance of classifying inventory

Netstock classifies your products in a nine-block grid by considering each item’s contribution and unit movement profile.

Consider an item that sells a large number of units but makes a small overall contribution to sales value. In a manufacturing environment, we look at the future manufacturing demand requirement to find that product’s space on the same matrix.

For an item like this, you could afford to order three or even four months of stock at a time and target a 99.99% fill rate. This will ensure that you never run out, but at the same time, you are not inflating your inventory because the value of stock for these items is small.

In essence, the policy you have now implemented for these items will lead to:

- Reduced orders: by ordering significant days of cover you reduce the number of orders you need to place over a year

- Improved fill rate: by targeting a high fill rate, you never run out of these products that are always in demand

- Minimal impact on inventory: as the items are low-value significant days of cover still only add a small amount to the overall inventory

By classifying products and then setting the appropriate inventory policy, you can balance your investment in inventory while achieving the desired fill rate target.

Let’s look at factors that are unique to the manufacturing industry.

- You have one component that goes into many different finished goods, and demand needs to explode for everything from finished products to raw materials.

- You have a product that you sell and that you use in the manufacturing process i.e. a product with multiple demand streams.

- If you have constrained capacity, your manufacturing facility cannot keep up during seasonal demand periods. Consequently, you might need to manufacture ahead of the season to ensure that you cope with those peak periods.

Bill of materials

The Bill of Materials (BOM) is a comprehensive list detailing all the raw materials, components, and subassemblies required to manufacture a finished product. It provides a roadmap for production and inventory management processes.

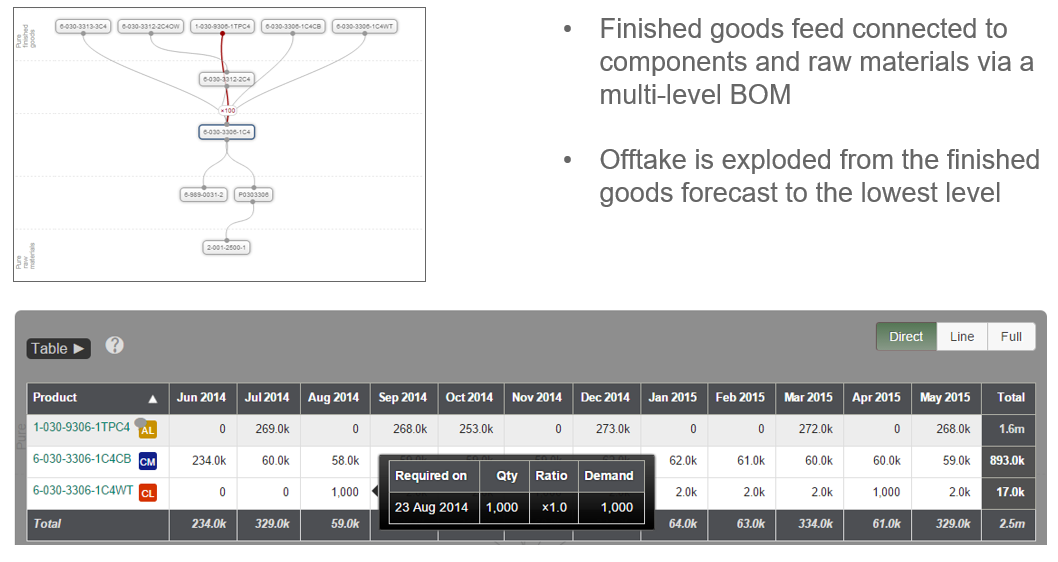

In the example below, we see a component of a bill of materials that goes into many finished goods. It’s also a sub-assembly made up of two raw materials. The demand from the finished product can be seen as dependent demand against the component in the table below.

There is a requirement to manufacture 1000 finished goods on the 23rd of August, which creates a demand against the component of 1000 (the ratio of the finished good to the component is one-to-one in this example, but of course could be any ratio).

Watch how Netstock manages Bill of Materials

Multiple demand streams

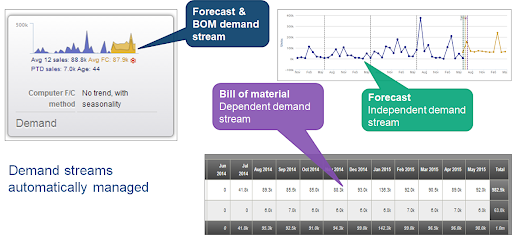

Using a demand and supply planning solution like Netstock, it automatically creates forecasts for every item using several sophisticated forecasting algorithms. The system provides the capability to amend these forecasts at an item or group level.

In this example, we have dual demand streams as follows:

- Item forecast plus,

- Dependent demand from a BOM explosion

Raw Materials

You might have a raw material that goes into many finished goods. If you run out of stock of that raw material, this will impact the ability to manufacture many of the finished products.

This could significantly impact your sales and disrupt your manufacturing plans. Consequently, you never want to run out of key raw materials, but you also do not want to overstock these products.

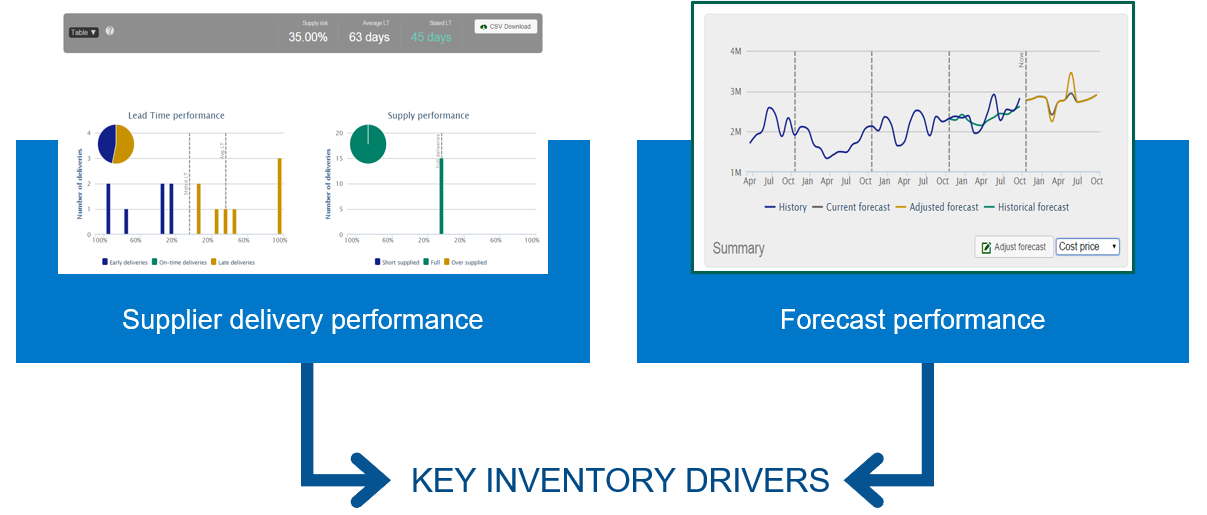

Netstock automatically tunes the levels for these critical raw materials/components, taking into account:

- Supplier delivery performance

- Variability of finished goods demand forecasts

- Length of the lead-time

- Minimum ordering constraints and

- Target fill rate

to ensure that the optimal level of stock is held for these key items.

Future Manufacturing plans

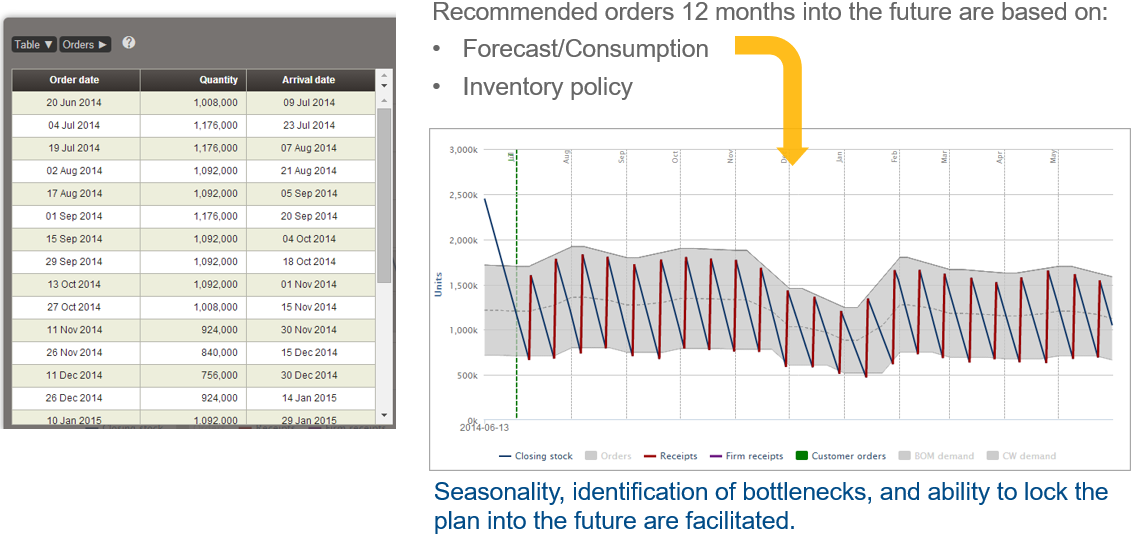

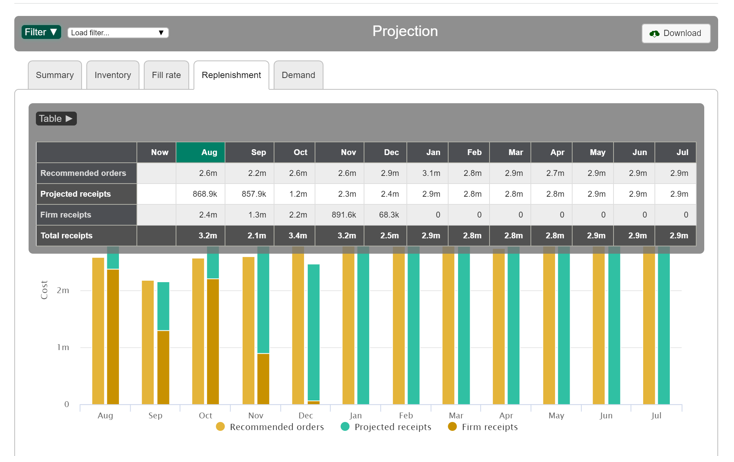

Netstock creates an ideal profile of inventory that you need to hold for every finished product. It then creates a manufacturing plan for the future for the next 12 months, by day, on a rolling 12-month basis. In the example shown below, you can see a manufacturing recommendation suggesting a planned replenishment every two weeks because it has been set up to order about two weeks’ worth.

The suggestion shows what quantity to plan and when it should arrive in stock. In this example, we can clearly see the seasonal demand. As the plan is graphically shown, it is easy to identify bottlenecks, so that you can move production forward if required to ensure you don’t get overwhelmed during peak periods.

6 Capacity planning: short and long-term

Capacity short term

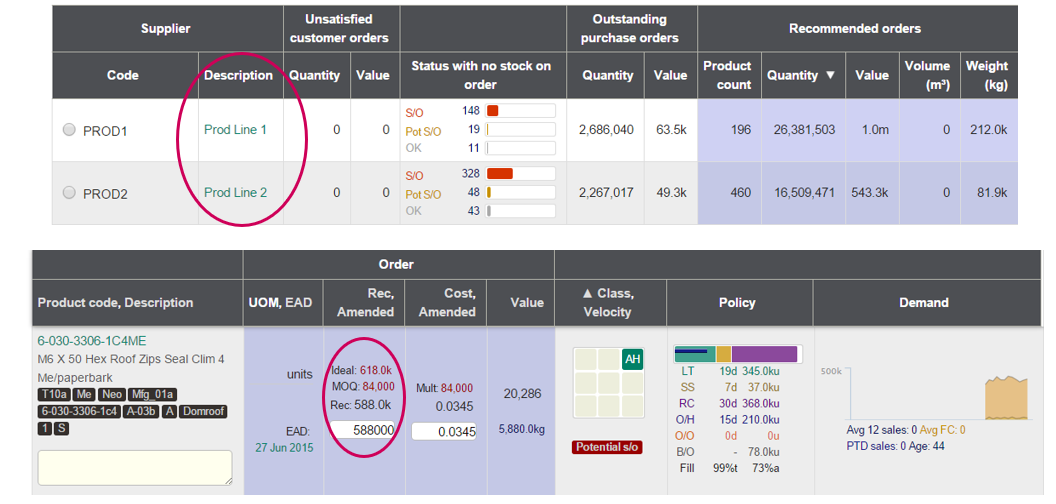

As we can summarize data in Netstock, by any grouping available in your ERP, you can see where the bottlenecks will occur by production line or work center and adjust your plans accordingly.

Capacity long term

Finally, you need to ensure that you have a long-range view of your capacity. In the example below, you can see a view for the next 12 months. This view is shown in monetary terms, but of course, you could look at it in volume or weight or production hours.

You can see that the recommended plan for this specific production facility is varying into the future, and the peak would be in January. If 2.6 million was your capacity constraint, you are okay from August to October, but you will start having problems after that point. In consequence, you may need to start making some additional stock ahead of the peak period or add extra shifts.

Considering all these factors and anomalies, you can quickly see that managing inventory in a manufacturing environment is extremely complex and not something that can be done easily in a spreadsheet.

7 Mastering inventory management in manufacturing

Managing inventory in manufacturing is complex, but it’s crucial for operational efficiency and customer satisfaction. Adopting effective inventory management solutions is essential for success. With the right tools and strategies in place, manufacturers can not only streamline their operations but also gain a competitive edge in the market, ensuring sustainable growth and profitability for years to come.

If your current processes and systems do not support or handle the complexities we’ve discussed, now is the time to explore alternatives.

.png)